Although cellular and WiFi networks are not required by code, they are crucial for communication. More than 400,000 wireless E-911 calls are made every day…

Image Source: http://bit.ly/1EqvCDv

Source: www.facilitiesnet.com

>” MISTAKE 1: Thinking it’s someone else’s problem.

Don’t let your architect avoid the issue. Design a building with adequate wireless coverage for public safety, cellular, and WiFi. […] WiFi networks are also widely used for Internet traffic and to support building management systems (BMS), Smart Grid, point of sales, audio visual, security, and more. The impact of wireless devices is only expected to increase. Mobile devices are expected to account for 61 percent of worldwide Internet traffic by 2018, compared to 39 percent from wired devices, according toCisco.

MISTAKE 2: Confusion.

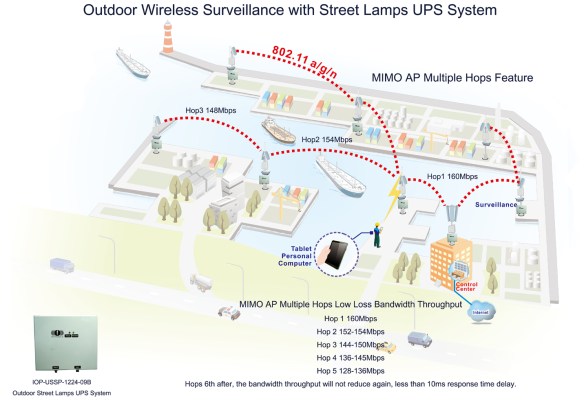

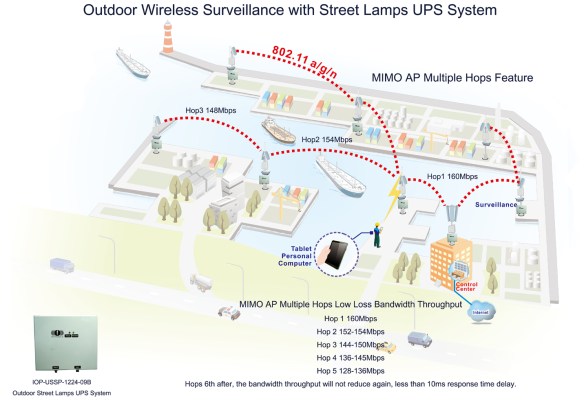

Confusing the types of wireless technologies available and/or facility requirements is another pitfall. You don’t want to plan for one type and learn later that technology for common functions is missing. Technologies have different requirements for power, spacing between devices, type of cables, head-end requirements, etc. Therefore, a key factor is to understand each technology thoroughly so it can be planned and implemented properly.

To put it briefly, there are two major wireless technologies — WSP, which are your wireless carriers networks (AT&T, T-mobile ,Verizon, etc.), and WiFi technology, which is a wireless local area network (WLAN) based on Institute of Electrical and Electronics Engineers (IEEE) 802.11 standards.

Both of these transmit via radio frequencies. WiFi (WLAN), however, uses an unlicensed spectrum that transmits at frequencies 2.4GHz and 5 GHz, which are considerably higher frequencies than used for cellular service, which is on a licensed spectrum transmitting within 698MHz-2.7GHz.

MISTAKE 3: Bad budgeting.

Often, contractors develop their budget based on square footage, but wireless isn’t so simple. The price can vary significantly based on the complexity of the needs, the supporting frequencies, coverage area, number of users, and more. By developing preliminary wireless design, IT consultants can provide the owner/operators with a more accurate cost.

Regardless of the facility, it’s no longer a matter of if wireless will be required, just a question of whether you want to plan early before you build, or pay a premium later. IT consultants can help facility managers plan, select the best wireless options to meet end-user needs, and stay to up-to-date with local codes (where required). Furthermore, an IT consultant can better develop a realistic wireless budget for the owner and provide the architect-engineer-construction team with infrastructure requirements, such as pathways, telecom room sizes and locations, power, and cooling, without sacrificing the architect’s vision. Generically speaking, the fee for an IT consultant is insignificant to the overall project cost, and may ultimately save the owner money and headache. Be prepared for what’s to come. Overlooking this need early can often cause a major regret later.

Gislene D. Weig, electrical engineer, RCDD, is a senior consultant at PlanNet Consulting, where her core business involves U.S. and Latin American markets focused on large-scale projects that include voice/data, wired and wireless communication systems, and data network design. She can be reached at gweig@plannet.net.”<

See on Scoop.it – Green Building Operations – Systems & Controls, Maintenance & Commissioning