Globalization seems to be looked on as an unmitigated “good” by economists. Unfortunately, economists seem to be guided by their badly flawed models; they miss real-world problems. In …

Globalization seems to be looked on as an unmitigated “good” by economists. Unfortunately, economists seem to be guided by their badly flawed models; they miss real-world problems. In …

Monthly Archives: December 2016

Benchmarking Buildings by Energy Use Intensity (EUI)

There are many metrics and measurements when it comes to evaluating energy as we use it in our daily lives. In order to compare between different sources or end uses we often have to make conversions in our terms so that our comparisons are equitable. This may be further complicated as different countries often use different standards of measure, however, we will convert to common units.

Benchmarking

Benchmarking is the practice of comparing the measured performance of a device, process, facility, or organization to itself, its peers, or established norms, with the goal of informing and motivating performance improvement. When applied to building energy use, benchmarking serves as a mechanism to measure energy performance of a single building over time, relative to other similar buildings, or to modeled simulations of a reference building built to a specific standard (such as an energy code). (1)

Benchmarking is a common practice in buildings to establish existing consumption rates and to identify areas that require improvement and to help prioritize improvement projects. These benchmarks can be established for a building, system within a building, or even a larger campus, facility or power source. Usually an energy or facility manager will determine energy consumption over a fixed period of time, 1 to 3 years, and compare it to similar facilities. Normalized by gross square footage of the building the EUI is usually expressed as kBtu/sf per year.

Energy Intensity (EI) of a Country

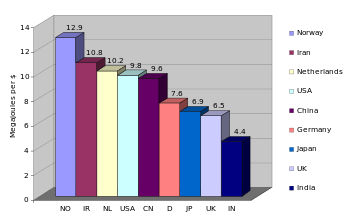

Figure 1: Energy Intensity of different economies The graph shows the amount of energy it takes to produce a US $ of GNP for selected countries. (2)

Not to be confused with Energy Use Intensity, Energy Intensity is an economic measure of energy use normalized by the GDP of a country and is considered a measure of a Nation’s Energy Efficiency. Countries with a high EI have a higher cost to convert energy into GDP, whereas countries with low EI have lower costs of converting energy into GDP. Many factors contribute to the EI value, including climate, energy sources and economic productivity. (2)

Energy Use Intensity (EUI)

The EUI of a building includes the electrical power use and heating fuel consumption for heating and hot water generation. Many facilities require different loads according to their primary use or function, including cooling and refrigeration. For the comfort of occupants electricity is needed for lighting and plug loads to meet the functioning needs of the equipment in the facility. Heating, ventilation and air conditioning (HVAC) may require electricity or another fuel such as natural gas. Hot water may be generated with electricity or a fuel. A site may also have solar PV or hot water, wind power, and daylighting programs. There are also many strategies which may be employed by building operators to reduce loads and energy consumption including controls, storage, micro-grid, purchasing offsets, etc.

When comparing buildings, people not only talk about total energy demands, but also talk about “energy use intensity” (EUI). Energy intensiveness is simply energy demand per unit area of the building’s floorplan, usually in square meters or square feet. This allows you to compare the energy demand of buildings that are different sizes, so you can see which performs better.

EUI is a particularly useful metric for setting energy use benchmarks and goals. The EUI usually varies quite a bit based on the building program, the climate, and the building size. (3)

_1.png)

Figure 2. Typical EUI for selected buildings. This graph is based on research EPA conducted on more than 100,000 buildings (4)

Site Energy vs Source Energy

As we go forward into the future, it is rather unclear how current events will affect the international agreements on reducing carbon consumption. However, generally speaking, renewable energy sources are seen to becoming more economic for power production. For many facilities this means that supplementing existing grid sources for power with on-site power production is making economic sense. Future building improvements may include sub-systems, batteries and energy storage schemes, renewable sources or automated or advanced control systems to reduce reliance on grid sourced power.

The energy intensity values in the tables above only consider the amount of electricity and fuel that are used on-site (“secondary” or “site” energy). They do not consider the fuel consumed to generate that heat or electricity. Many building codes and some tabulations of EUI attempt to capture the total impact of delivering energy to a building by defining the term “primary” or “source” energy which includes the fuel used to generate power on-site or at a power plant far away.

When measuring energy used to provide thermal or visual comfort, site energy is the most useful measurement. But when measuring total energy usage to determine environmental impacts, the source energy is the more accurate measurement.

Sometimes low on-site energy use actually causes more energy use upstream. For example, 2 kWh of natural gas burned on-site for heat might seem worse than 1 kWh of electricity used on-site to provide the same heating with a heat pump. However, 1 kWh of site electricity from the average US electrical grid is equal to 3.3 kWh of source energy, because of inefficiencies in power plants that burn fuel for electricity, and because of small losses in transmission lines. So in fact the 2 kWh of natural gas burned on site is better for heating. The table below provides the conversion factors assumed by the US Environmental Protection Agency for converting between site and source energy. (3)

References:

(1) BUILDING ENERGY USE BENCHMARKING https://energy.gov/eere/slsc/building-energy-use-benchmarking

(2) ENERGY INTENSITY https://en.wikipedia.org/wiki/Energy_intensity

(3) MEASURING BUILDING ENERGY USE https://sustainabilityworkshop.autodesk.com/buildings/measuring-building-energy-use

(4) WHAT IS ENERGY USE INTENSITY (EUI)? https://www.energystar.gov/buildings/facility-owners-and-managers/existing-buildings/use-portfolio-manager/understand-metrics/what-energy

Aluminum Metal Advancements in Sustainability

Can the idea of sustainability be determined by metrics? The answer is “Of course”, as any type of improvement can be measured. We understand it is far more efficient to recycle aluminum than it is to produce it the first time, which we call this value embodied energy. However, since refining represents a significant proportion of manufactured costs there becomes a premium on recycling used aluminum. Not only are the savings in energy, they are also in emissions of GHG’s.

Novelis reports.

“Recycling aluminum produces 95 percent fewer greenhouse gas (GHG) emissions and requires 95 percent less energy than primary aluminum production, enabling Novelis to achieve lower GHG emissions despite increasing global production capacity.” (1)

Novelis also reports improvements in Energy Intensity and Water Intensity metrics.

Significant gains were also made in fiscal 2016 as it relates to water and energy intensity. Novelis achieved a 22 percent reduction in water intensity and a 24 percent reduction in energy intensity for the 2007-2009 baseline. (1)

Novelis Core Business

Novelis produces close to 20 percent of the world’s rolled aluminum products and we are strategically located on the four continents where aluminum demand is the greatest: North America, South America, Europe and Asia. Our dedication, innovation and leadership have made us the number one producer of rolled aluminum in Europe and South America, and the number two producer in North America and Asia. We also are the world’s largest recycler of used beverage cans, which comprise a critical input to our operations. Quite simply, recycling is a core element of our manufacturing process. (2)

Figure 1: Novelis Opens World’s Largest Aluminium Recycling Facility (3)

Novelis has officially opened the “world’s largest” aluminium recycling centre located adjacent to the company’s rolling mill in Nachterstedt, Germany and costing over £155m.

The recycling centre will process up to 400,000 metric tons of aluminium scrap annually, turning it back into high-value aluminium ingots to feed the company’s European manufacturing network.

“The Nachterstedt Recycling Centre is a significant step toward our goal to be the world’s low-carbon aluminium sheet producer, shifting our business model from a traditional linear approach to an increasingly closed-loop model,” said Phil Martens, president and chief executive officer of Novelis. (3)

References:

(2) http://novelis.com/about-us/assets-and-capabilities/

(3) http://www.ciwm-journal.co.uk/novelis-opens-worlds-largest-aluminium-recycling-facility/

Related Posts:

Embodied Energy https://duanetilden.com/2014/12/10/embodied-energy-a-measure-of-sustainability-in-buildings-construction/

Energy Efficiency https://duanetilden.com/2016/06/19/measuring-and-monitoring-energy-efficiency/

The Secret Life of Plants

by Tristan Wang On a night in 1966 interrogation specialist Cleve Backster taught how to perform lie detection to policemen. On a whim, Backster attached electrodes of a galvanometer to a nearby dr…

Source: The Secret Life of Plants