The significance of heating and cooling technologies for Europe was again underlined at a major conference on district energy in Brussels. Miquel Arias Caňete, European Commissioner for Climate Action and Energy, was among a number of speakers who addressed the Heating and Cooling in the European Energy Transition Conference last week. Nearly half of Europe’s energy consumption flows into the heating of buildings and industrial processes. Some 15% of this energy is coming from renewables, suc

Source: www.cospp.com

>”[…]

Nearly half of Europe’s energy consumption flows into the heating of buildings and industrial processes. Some 15% of this energy is coming from renewables, such as biomass and solar panels. Around 1 billion Euro per day is needed to pay for fuel imports.

In his opening address, Caňete stressed that heating and cooling is a sector that deserves maximum attention because of its high share in using fossil energy. He referred to the sector as “the missing piece in the energy and emissions debate”.

A large proportion of buildings have poor energy performance and without specific action, he said it will be a long time before the situation improves. In industry, he advocated more synergy is needed between industry and the heating of buildings with waste energy.

“Next to that, electricity and heat supply has to be integrated. In times of excess renewable electricity, it should be used for heating purposes. This is especially the case since heat use in the EU is energy wise about 2.5 times higher than electricity use. Under European Structural and Investment Funds (ESIF), some €38 billion has now been allocated by Member States for energy efficiency, local renewable energy and local transport.”

Pieter Liese, MEP, said that a EUR1bn payment for energy per day is sent from the EU to countries with a doubtful regime such as Russia, Qatar, Saudi Arabia. He pleaded for a common European policy and approach. He stated that although politicians like to talk about electricity, it is clear that improving heating and cooling processes is a more sensible subject.

According to Ulrich Schmidt, chairman of the European Heating Industry, 75% of Europe’s housing stock are energy inefficient and 65% of gas boilers are old and inefficient while 40 % of homes date back to before 1960.

“Owners of existing equipment are reluctant to replace their appliances since the pay-back time from the benefit of less fuel consumption is too long. Moreover, old-fashioned boilers are considered by consumers to be more reliable than modern ones.”

Ligia Noronha, Director of Technology, Industry and Economics, United Nations Environment Programme (UNEP), stated that energy efficiency is a key component of the EU energy transition. She highlighted the Global District Energy in Cities Initiative. It is an analysis of 45 leading cities. District heating is seen as a major instrument in improving energy utilisation. By 2050, Europe could meet 50% of its heat demand via district heating.

John Dulac from the IEA said that as much heat is thrown away by inefficient processes as what is needed in the EU.

“‘SILO’ thinking is the big problem. The share of cogeneration in electricity production has to increase drastically. Moreover, electricity production and heat/chill production have to be integrated. “

Paul Voss, Managing Director of Euroheat & Power, warned that if the EU failed to integrate its heating and cooling potential and the current trend in emissions reduction continues, only 60% of the overall reduction target will be reached by 2050.

Three workshops were also part of the itinerary of the day, with Professor Hans-Martin Henning, Deputy Director for solar energy systems at the Fraunhofer Institute outlining a vision for the sector for 2050.

He said heat demand in buildings can be reduced from 30% to 50% by 2050 and added that solar thermal heating, biomass and CHP can play a major role in reducing CO2 emissions of buildings.

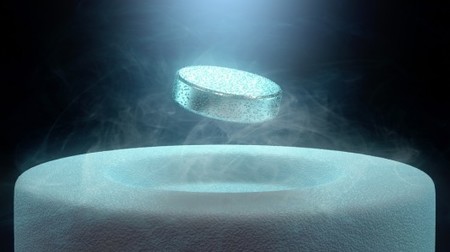

Henning also showed the audience how storing energy as heat is much cheaper than other ways of storing energy.

“Germany needs 700 GWh of heat storage, 60 GWh of pumped hydro and 24 GWh of batteries. CHP has excellent possibilities of storing heat and is very suitable for balancing renewable electricity,” he said.

“<

See on Scoop.it – Green & Sustainable News