See on Scoop.it – Green Building Design – Architecture & Engineering

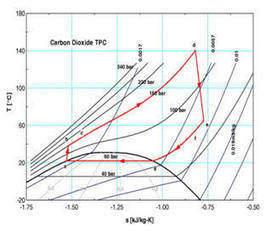

Working fluids with relatively low critical temperature and pressure can be compressed directly to their supercritical pressures and heated to their supercritical state before expansion so as to obtain a better thermal match with the heat source.

>Chen et al. [1-3] did a comparative study of the carbon dioxide supercritical power cycle and compared it with an organic Rankine cycle using R123 as the working fluid in a waste heat recovery application. It shows that a CO2 supercritical power cycle has higher system efficiency than an ORC when taking into account the behavior of the heat transfer between the heat source and the working fluid. The CO2 cycle shows no pinch limitation in the heat exchanger. Zhang et al. [4-11] has also conducted research on the supercritical CO2 power cycle. Experiments revealed that the CO2 can be heated up to 187℃ and the power generation efficiency was 8.78% to 9.45% [7] and the COP for the overall outputs from the cycle was 0.548 and 0.406, respectively, on a typical summer and winter day in Japan [5].

Organic fluids like isobutene, propane, propylene, difluoromethane and R-245fa [12] have also been suggested for supercritical Rankine cycle. It was found that supercritical fluids can maximize the efficiency of the system. However, detailed studies on the use of organic working fluids in supercritical Rankine cycles have not been widely published.

There is no supercritical Rankine cycle in operation up to now. However, it is becoming a new direction due to its advantages in thermal efficiency and simplicity in configuration.<

See on www.eng.usf.edu